Transforming Bioreactor Flow Control with One Partner, One Platform

How IMI helped a bioreactor manufacturer cut costs by 50%, shrink system size by 70%, and boost gas flow precision - all with one integrated solution.

Too many components, too many suppliers?

To support optimal cell growth in a bioreactor, precise control of gases like oxygen and carbon dioxide is essential. However, one bioreactor manufacturer faced challenges with a bulky and complex mass flow controller setup.

Their system involved a maze of tubes, fittings, and cables, making it hard to assemble and prone to leaks and faults. Sourcing parts from five different suppliers further increased costs and troubleshooting difficulties. The manufacturer needed a more compact, efficient solution that would reduce assembly time, lower costs, minimize the footprint, and improve reliability.

IMI Solution: Smarter Flow Control with Fewer Parts, Lower Cost, and Greater Precision

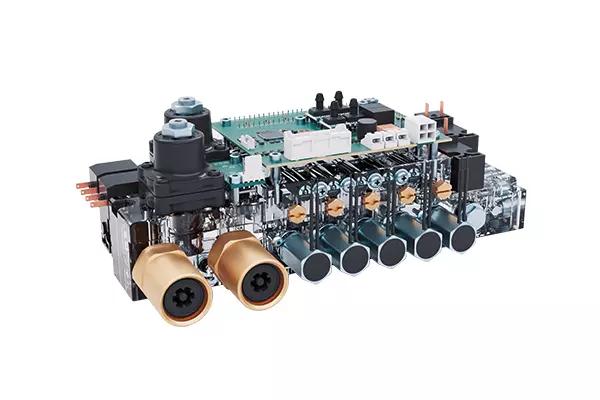

By partnering with IMI, the bioreactor manufacturer replaced five suppliers with one trusted source—receiving a streamlined, flexible solution. IMI’s design, based on four standard mass flow controllers and a custom manifold, reduced tubes, connectors, and cables, shrinking the footprint by 70% and minimizing leak risks.

IMI manages the entire process: sourcing, assembly, and leak testing, delivering a ready-to-install unit. This simplifies logistics and speeds up support, with expert engineers on hand. The result? A 50% cost reduction and improved performance.

Unlike the original system, which controlled gas flow down to 1%, IMI’s solution achieves 0.05% resolution—expanding control range and reducing scale-up needs. Compact, cost-effective, and reliable, it’s a complete upgrade.

By providing a compact, cost-effective, and reliable solution, IMI streamlined the assembly process, reduced costs, and improved performance for the manufacturer.

Featured Products