Custom fluidic integration for compact, high-performance anesthesia systems

IMI delivers tailored components and integrated manifolds to enhance control, efficiency, and space optimization.

Challenges with space, complexity and control in anesthesia system design?

A medical device manufacturer set out to redesign their anesthesia machine with the end-user in mind—focusing on the anesthesiologist’s need for intuitive control, comfort, and maximum functionality. They faced challenges in integrating multiple components within a compact footprint while maintaining high performance and minimizing gas waste.

IMI develops market-leading customised solution for anesthesia

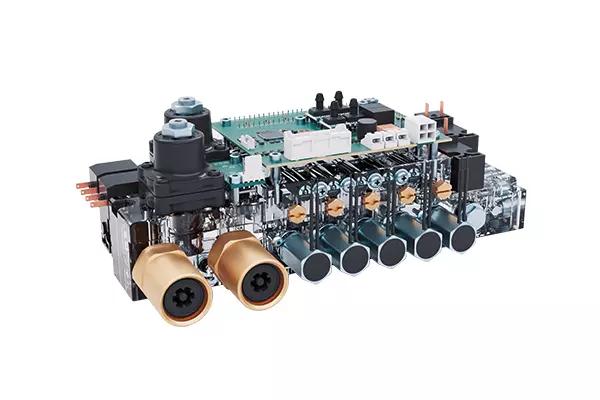

IMI leveraged its global expertise to develop and deliver 20 custom-configured components, mostly adapted from standard products to meet specific functional needs. To simplify installation and reduce system size, many components were integrated into sub-assembly manifolds.

One of the innovation highlight was a modified pressure regulator that allowed continued gas flow at lower pressures—maximizing the use of anesthesia gas bottles and reducing waste. With market-leading proportional valve technology and a strong track record in fluidic control, IMI provided a compact, efficient, and reliable solution that strengthened the customer’s advantage in designing advanced anesthesia systems.

Featured Products